There are many types of graphene, each depending on how it was produced. Learn how to differentiate graphene based on its production process. This will allow you to select the right type of graphene for your application.

How is graphene produced?

Graphene has been isolated and characterized for the first time ever in 2004 thanks to the scotch-tape method. This method proved that graphene was not just a theory, but a reality.

The Scotch tape method is not transferable to industrial production of graphene, but it was a stepping-stone. Several different production processes have emerged since graphene was first isolated.

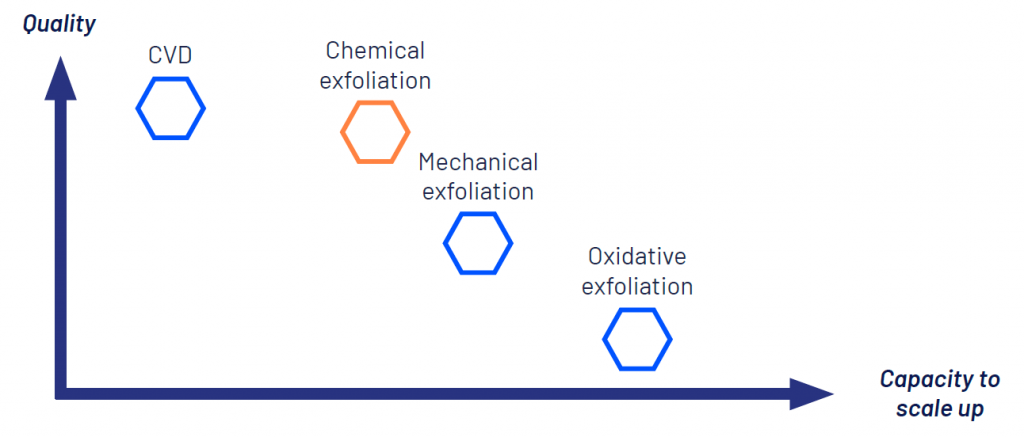

Two different strategies can be applied:

- Bottom Up: Graphene produced from gases by Chemical Vapour Deposition (CVD)

- Top Down: Graphene produced from graphite by exfoliation (chemical, mechanical, oxidative)

These different processes produce various quality and types of graphene.

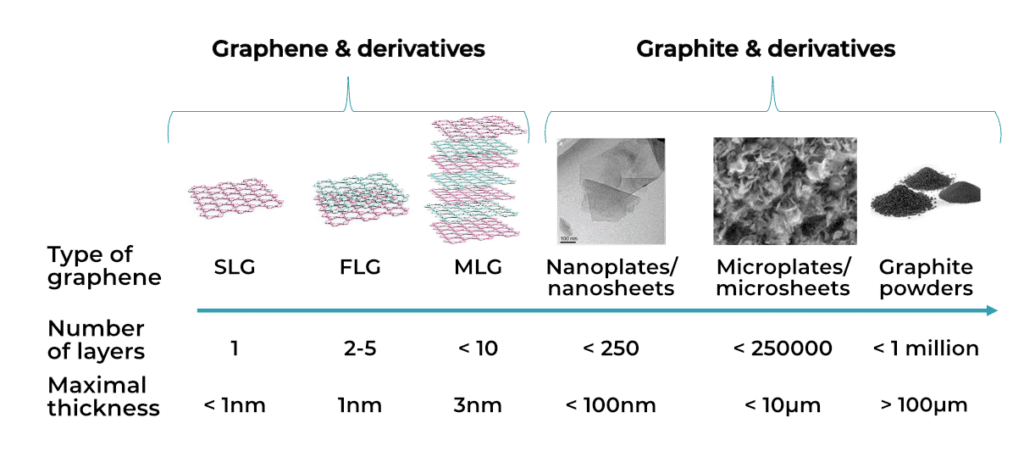

We can segment the graphene family in 2 ways:

- Material Thickness

- Purity

Material Thickness

Graphene is limited to 10 layers, so is less than 3 nm thick. Today, very few companies are able to produce this type of graphene.

- SLG: Single Layer Graphene (1 Layer)

- FLG: Few Layer Graphene (2-5 Layers)

- MLG: MultiLayer Graphene (<10 Layers)

- GNP: Graphite NanoPlates (<250 Layers)

For such a 2D material, thickness is a critical parameter. The thinner the material, the better the properties will be.

Purity of Graphene

Functional groups, even in low quantities, decrease its performance as an anticorrosion agent or thermal and electrical conductor. The degree of functionalization and the level of defects depend greatly on the method of production.

There are five main methods:

Comparing Graphene

When choosing graphene, you should be careful of the quality and scalability of the graphene. It all depends on the application and how you want to use graphene.