To date, recommendations on graphene characterization have been drawn up, with a view to global standardization.

Graphene Quality : A key factor

Although most graphene producers provide technical data, the studies are difficult to compare and it is impossible to know whether measurements are carried out systematically.

As a result, there is a distinct lack of transparency as to the quality and price levels of graphene producers. This makes it very difficult for a potential user to identify a serious graphene supplier.

Research conducted by the National University of Singapore (NUS) has proposed an analysis and comparison protocol, based on the study of graphene quality from 60 manufacturers. Results: graphene is generally of poor quality and not optimal for many applications.

The study tends to show that most graphene manufacturers produce graphite microplatelets, not graphene. Several local initiatives have taken shape, in order to develop graphene quality verification programs. In Europe, this work is settled up in cooperation with the LNE, INERIS or NPL.

Quality assessment

1 – Ultraviolet–visible spectroscopy (UV-Visible)

With only absorbing 2% of the visible light, one layer of graphene is transparent to the human eye.

Graphene absorbs however at a very characteristic wavelength in the ultraviolet range. It is well described in the literature that pristine graphene exhibits a characteristic absorbance peak at 269 nm. This peak can be attributed to π -> π* transitions of aromatic C bonds.

Graphene oxide on the other hand has numerous defects and functional groups that interrupt the electronic continuity within the honeycomb structure.

Therefore, more energy is required for π -> π* transition of the aromatic C bonds, explaining why the absorbance peak is shifted to shorter wavelengths.

The shoulder found at 300 nm is described in the literature as n -> π* transitions of the carbonyl groups typical of graphene oxide.

The UV-Visible spectroscopy is a very simple tool to get a first idea of the quality of a graphene dispersion and to investigate the stability over time.

2 – Raman Spectroscopy

Raman spectroscopy is the main technique to consider when assessing graphene quality.

Since the discovery of graphene in 2004, many research groups have been working to decipher its Raman spectrum and extract all the information available. It is a difficult task, requiring real expertise to interpret the data correctly.

From a more simple point of view, the three main modes already provide many information about the quality of the material. In general, intensity ratios and Full Width Half Maximum (FMWH) provide the information needed to assess graphene quality.

- G mode is the reference of all comparison because it represents the carbon honeycomb structure of graphene.

- D mode is sensitive to faults and functional groups.

- 2D mode is very sensitive to the thickness of the graphene.

The Raman spectrum of graphene oxide (GO) is evidently different compared to graphene, due to the presence of numerous functional groups.

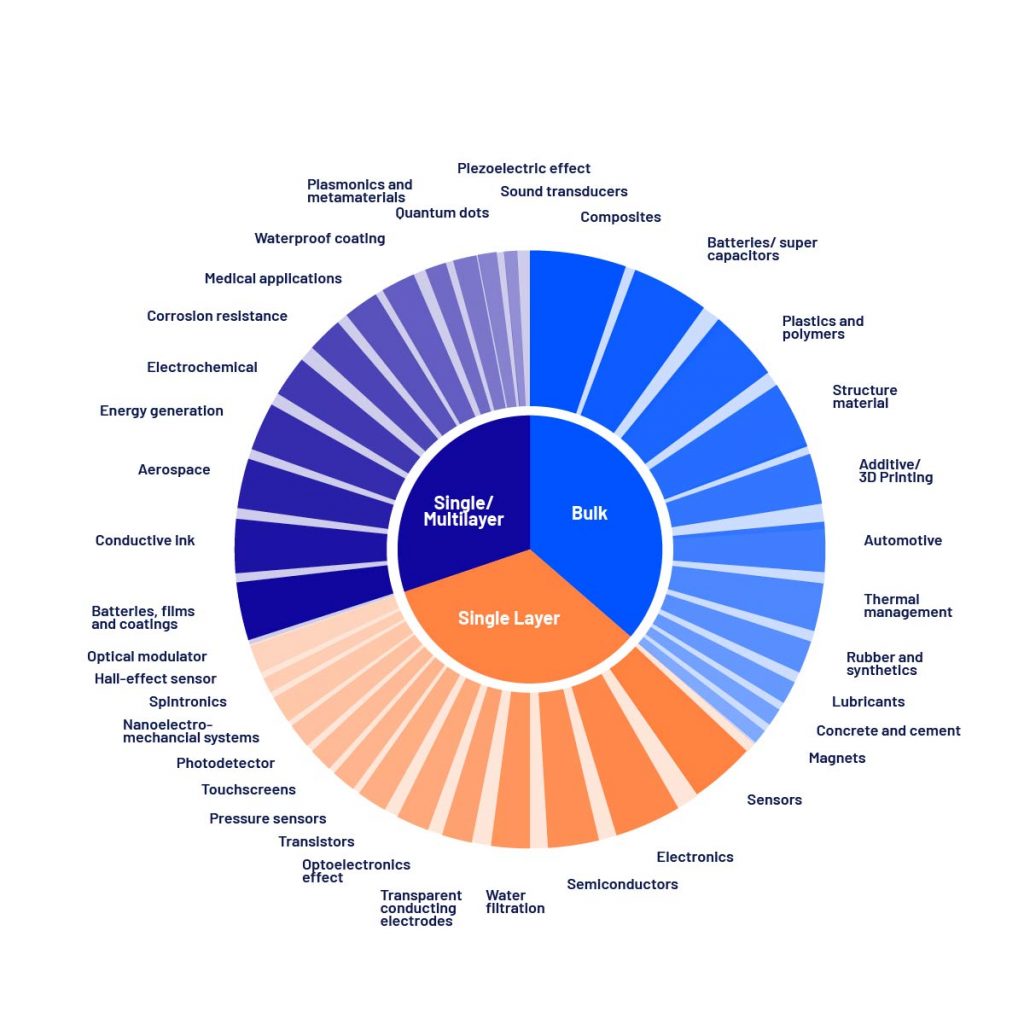

Graphene applications

It is important to remember that the efficiency of graphene in different applications relies directly on its structure and properties as shown on the figure presented below.

Source: the Graphene Council

Source: the Graphene Council