Il existe de nombreux types de graphène, chacun dépendant de la manière dont il a été produit. Apprenez à différencier le graphène en fonction de son processus de production. Cela vous permettra de sélectionner le bon type de graphène en fonction de votre application.

Comment le graphène est-il produit ?

Le graphène a été isolé et caractérisé pour la première fois à l’aide de ruban adhésif. Cette découverte a prouvé que le graphène n’était pas seulement une théorie, mais bien une réalité.

La méthode du ruban adhésif n’est absolument pas transposable pour une production industrielle de graphène. Néanmoins, la découverte majeure de ce matériau a donné lieu au développement de plusieurs procédés de production.

Deux stratégies peuvent être appliquées :

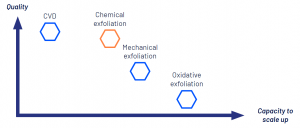

- Bottom Up : Graphène synthétisé à partir de gaz organiques, par dépôt chimique en phase vapeur (CVD)

- Top Down : Graphène produit à partir de graphite, par séparation et isolation de feuillets de graphène (exfoliation chimique, mécanique ou par oxydation)

Ces différents procédés donnent lieu à des graphène de format et qualité variés.

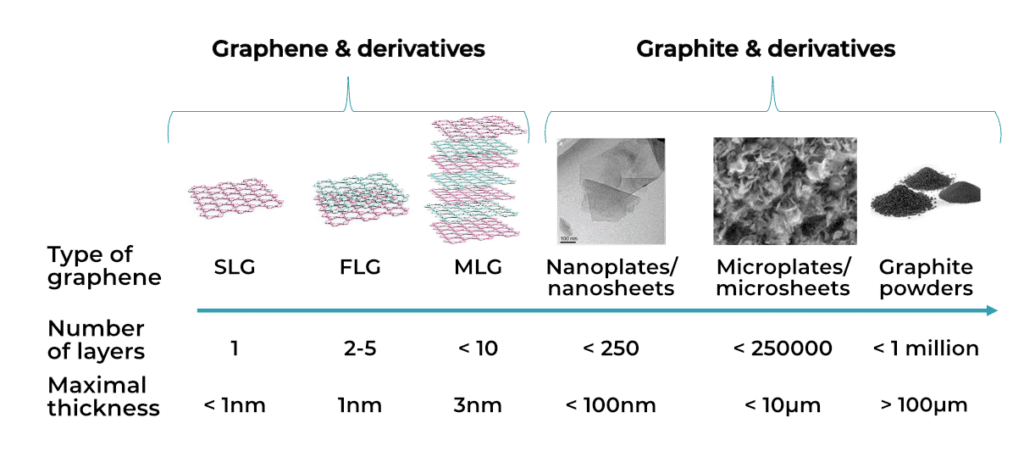

La famille du graphène peut être segmentée selon deux paramètres :

- L’épaisseur du matériau

- La pureté

Épaisseur du matériau

Les experts du graphène limitent l’utilisation du terme « graphène » à des matériaux dont l’épaisseur est inférieure ou égale à 10 couches, soit 3 à 4 nm. Aujourd’hui, peu d’entreprises et de laboratoires sont capables de produire un tel graphène.

- SLG : Single Layer Graphene (1 couche)

- FLG : Few Layer Graphene (2-5 couches)

- MLG : MultiLayer Graphene (<10 couches)

- GNP : Graphite NanoPlates (<250 couches)

Pour un tel matériau 2D, l’épaisseur est un paramètre critique. Plus le matériau est fin, meilleures seront ses propriétés.

Pureté

Les groupes fonctionnels ou impuretés, même en faible quantité, diminuent les performances anticorrosion ou la conductivité thermique et électrique. Le degré de fonctionnalisation et, par conséquent, le niveau de défauts, sont fortement liées à la méthode de production.

Il existe cinq méthodes principales :

Comparaison des différents graphènes

Pour choisir un type de graphène, il faut faire attention à sa qualité et à son adaptabilité. Tout dépend de l’application souhaitée.